Beyond the Blueprint: Designing with Durability – A Guide to Metal Selection.

-

Henry Cook

- /

- 10.15.2025

- /

- 0

- /

- Views 14680

In the world of bespoke construction and design, the choice of material is paramount, often dictating the longevity, performance, and aesthetic appeal of the final product. Far beyond mere aesthetics, selecting the right metal is a critical engineering decision that underpins the entire project's success. It's the difference between a structure that endures for decades and one that succumbs to the elements or stresses prematurely. Understanding the properties and applications of various metals is the first step towards achieving true durability.

Every project, whether a robust industrial component or an elegant architectural feature, presents a unique set of challenges and environmental factors. From corrosive outdoor environments to high-stress structural applications, the metal chosen must be capable of withstanding these forces without compromise. This thoughtful approach ensures not only structural integrity but also minimizes maintenance requirements and extends the lifespan of the investment, delivering value that lasts.

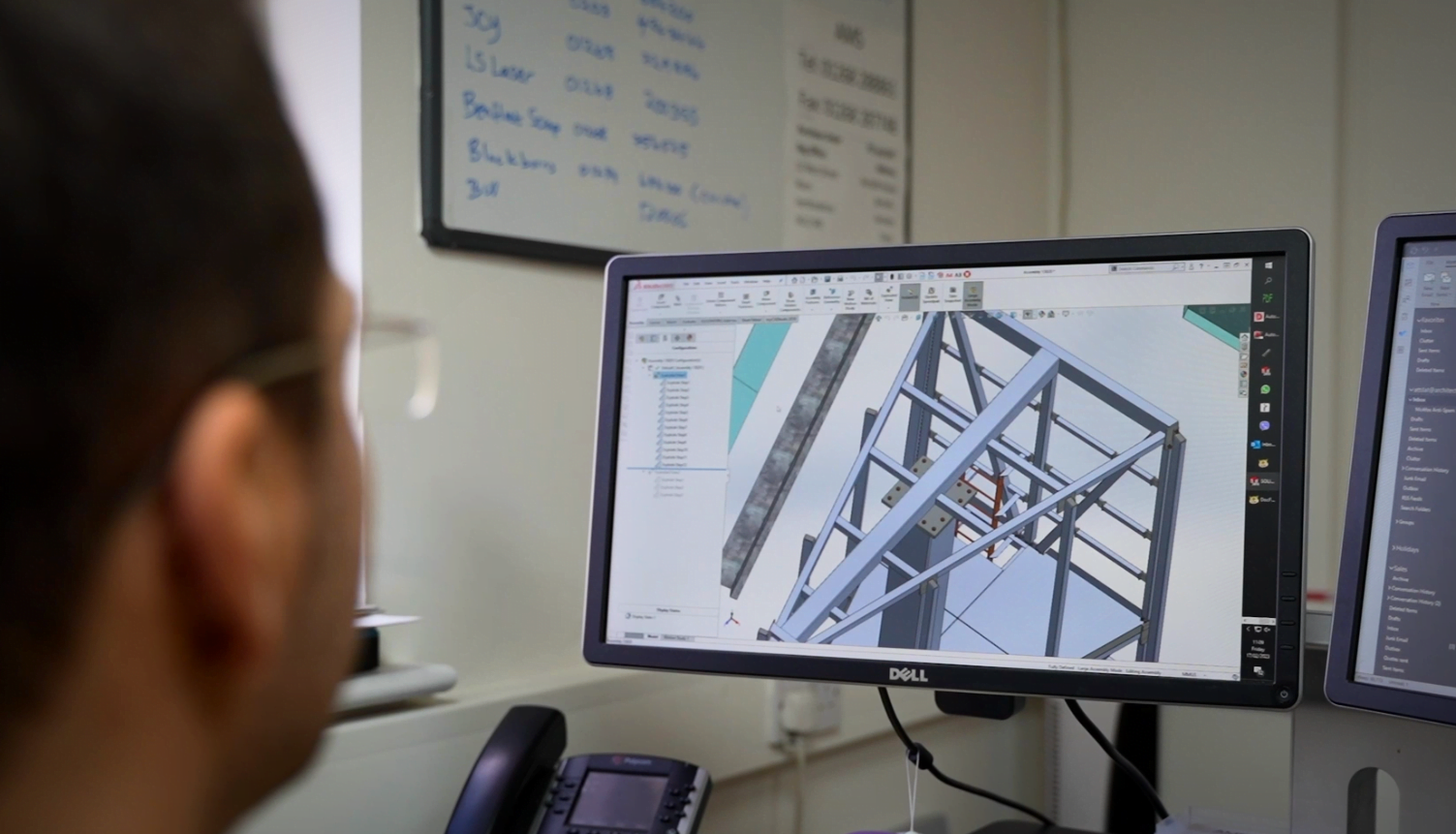

For clients seeking unparalleled quality in their bespoke projects, the expertise in `custom welding` and `metal fabrication` becomes indispensable. A skilled fabricator doesn't just cut and join; they act as a consultant, guiding clients through the intricate process of material selection. This foundational knowledge is crucial for crafting everything from intricate `metal design` elements to heavy-duty industrial components that perform flawlessly under specific conditions.

At Enzo's Custom Welding LLC, we understand that true craftsmanship begins long before the first weld is laid. Our commitment to excellence involves a deep dive into the project's requirements, considering factors like load-bearing capacity, environmental exposure, aesthetic integration, and budget constraints. This meticulous planning ensures that every piece we create is not only beautiful but also inherently strong and resilient.

The goal is always to deliver solutions that are not just functional but also enduring. This guide aims to shed light on the critical considerations involved in metal selection, empowering clients and designers to make informed decisions that will shape the future performance of their projects. We believe that a well-chosen material is the cornerstone of any successful and sustainable `custom metal works` endeavor.

Key Applications and Considerations in Metal Selection

-

Architectural Elements: For items like `steel railing` or decorative facades, aesthetics, corrosion resistance, and structural integrity are balanced. Stainless steel offers sleek looks and excellent durability, while powder-coated mild steel provides cost-effective customization.

-

Structural Components: In applications requiring high strength and load-bearing capacity, such as `structural welding` for building frames, high-grade carbon steel is often preferred. Its robust nature ensures safety and stability, though it requires proper finishing for corrosion protection.

-

Gates and Fencing: For `metal gate fabrication` and perimeter security, the balance between strength, weight, and weather resistance is key. Wrought iron offers classic appeal and formidable strength, while aluminum provides a lighter, corrosion-resistant alternative suitable for automated systems.

The Expert's Perspective: Navigating Metal Properties

Choosing the optimal metal is a nuanced process that involves weighing various engineering principles against practical considerations. Experts often emphasize the importance of understanding a metal's mechanical properties, such as tensile strength, yield strength, and hardness, which directly impact its ability to withstand stress and wear. For instance, a high tensile strength is critical for components under tension, while hardness is vital for resistance to abrasion.

Corrosion resistance is another significant factor, particularly for outdoor or marine applications. Stainless steel, with its chromium content, forms a passive layer that protects against rust, making it ideal for environments exposed to moisture or chemicals. In contrast, mild steel requires extensive surface treatment, such as galvanization or powder coating, to achieve comparable longevity in challenging conditions, adding to the overall project cost.

The weldability of a metal is also a paramount concern for any `welding shop`. Some alloys are inherently easier to weld than others, impacting fabrication time and potential for defects. Aluminum, for example, requires specific welding techniques and equipment due to its high thermal conductivity and propensity for oxidation. Understanding these characteristics allows a skilled `local welder` to select the most efficient and effective fabrication methods, ensuring structural integrity without compromising on quality.

While cost is always a consideration, focusing solely on the initial price per pound can be misleading. A cheaper material that requires more maintenance or has a shorter lifespan can quickly become more expensive in the long run. Investing in a higher-grade material upfront often translates to significant savings over the life of the product through reduced repair costs and extended service intervals. This long-term perspective is crucial for delivering genuine value to clients.

Final Thoughts on Enduring Design

The decision of which metal to use is never a simple one; it’s a confluence of science, engineering, and artistic vision. By carefully considering the specific demands of each project and consulting with experienced fabricators, clients can ensure their investments are not only aesthetically pleasing but also built to withstand the test of time.

Ultimately, designing with durability means making informed choices at every stage, especially concerning foundational materials. This proactive approach guarantees that the structures and designs brought to life will serve their purpose reliably and beautifully for years to come, reflecting a true commitment to quality and longevity.

Enzo's Custom Welding LLC

Enzo's Custom Welding LLC